Power up your machinery with our high-torque screw gears

Screw Gear Manufacturer

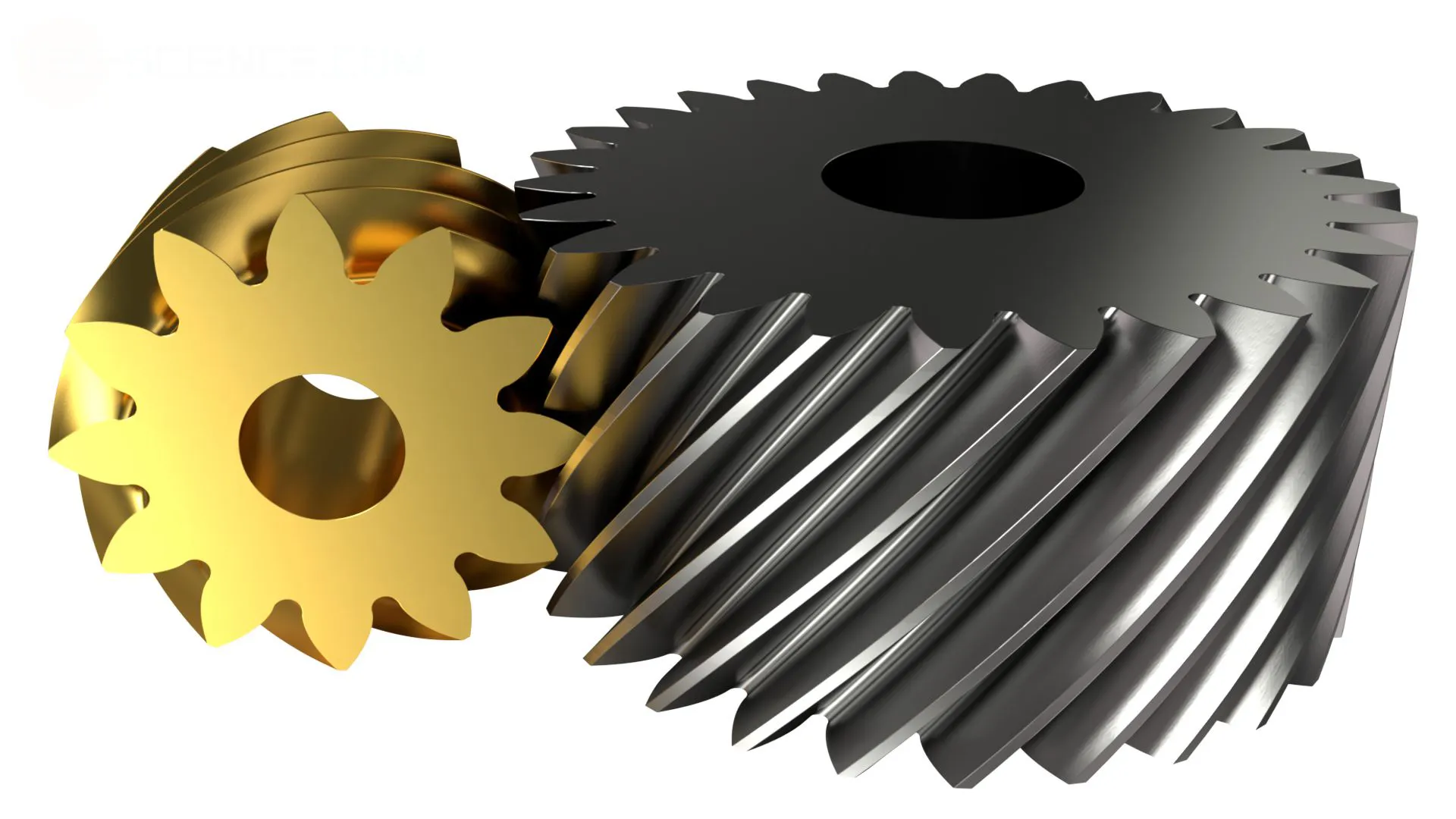

Helical gears are a pair of co-rotating helical gears with a twist angle of 45° on non-parallel, non-intersecting axes. Since the tooth contact is a point, its bearing capacity is low and it is not suitable for high power transmission. Since the power is transmitted by the sliding of the tooth surface, it is necessary to pay attention to lubrication when using helical gears. There is no limit to the combination of the number of teeth.

Multisport Ability

Due to their simple nature, helical gears can be driven by either a screw (worm gear) or the gear itself (rack and pinion), allowing the ability to move forward and backward through a single gear.

Fine Tuning & Space Saving

Helical gears are ideal for adjustment applications in tight areas. It enables precise adjustment and positive positioning.

Worm and Screw Gear

“Worm gear” and “screw gear” are two terms that are often used interchangeably to refer to the same type of gear system. This type of gear system consists of a worm gear (a cylindrical gear with a spiral thread) and a worm wheel (a gear with teeth that mesh with the threads of the worm gear).

The worm gear is driven by a shaft, and as it rotates, it turns the worm wheel, which rotates on a perpendicular axis. This system provides a high gear reduction ratio, which means that the output speed is much slower than the input speed, but the output torque is much higher than the input torque.

The terms “worm gear” and “screw gear” both refer to the same gear system, but “worm gear” is the more common term. The term “screw gear” is less commonly used but is still used to describe this type of gear system in certain contexts, such as in the context of screw jacks or other types of machinery that use screw threads for motion control.

Get Started

Why Did We Invent the Screw Gear?

- Linear to rotary or rotary to linear.

- Screws are inexpensive and can be found at any hardware store.

- You can make very fine, accurate, and precise adjustments.

- Eliminate the need and wait for special orders to mate worms.

- Immediate reduction of high speed to low speed with no additional gears.

- Strong build quality. Screw wares faster than Screw Gear, and screws are cheap.

- Great for hard to reach applications.

- Allows for quick and easy maintenance.

- Compatible with SAE & Metric screws and long threaded rods.

Features of Screw Gear

High Gear Reduction Ratio

Screw gears have a high gear reduction ratio, which means that they can provide a lot of torque output for a given input speed. This feature makes them useful in applications where high torque is required.

Compact Design

Screw gears have a compact design, which makes them useful in applications where space is limited. They can provide high torque output in a smaller space than other types of gear systems.

Self-locking

Screw gears are self-locking, which means that the worm gear can’t be turned by the worm wheel. This feature is useful in applications where it is important to prevent back driving or to maintain a specific position.

High Accuracy

Screw gears provide high accuracy in motion control, which makes them useful in applications where precise positioning is required.

Low Noise

Screw gears produce low noise when in operation, which makes them useful in applications where noise reduction is important.

Low Maintenance

Screw gears require relatively low maintenance compared to other types of gear systems, which makes them cost-effective in the long run.

Screw Gear for Sale

As a screw gear manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

“

Application of Screw Gear

Screw gears, also known as worm gears, have a range of applications in various industries. Here are some examples:

Automotive industry: Screw gears are used in automotive steering systems, where they help to transmit power from the steering wheel to the wheels of the vehicle. They are also used in gearboxes and transmissions to reduce speed and increase torque.

Industrial machinery: Screw gears are commonly used in industrial machinery, such as conveyor systems, packaging machines, and printing presses. They are particularly useful in applications where high torque is required in a compact space.

Construction machinery: Screw gears are used in construction machinery, such as cranes and excavators, to control the movement of the boom and other mechanical components.

“

Robotics: Screw gears are used in robotic systems to control the movement of joints and other mechanical components. They are particularly useful in applications where precision and accuracy are important.

Medical equipment: Screw gears are used in medical equipment, such as surgical robots and imaging machines, to control the movement of mechanical components with precision and accuracy.

Agriculture: Screw gears are used in agricultural machinery, such as tractors and combine harvesters, to control the movement of various mechanical components.

Aerospace: Screw gears are used in aerospace applications, such as aircraft landing gear systems, to control the movement of the landing gear.

Mining: Screw gears are used in mining machinery, such as coal cutters and boring machines, to control the movement of various mechanical components.

Military: Screw gears are used in military equipment, such as tanks and armored vehicles, to control the movement of various mechanical components.

Marine: Screw gears are used in marine applications, such as ship propulsion systems, to control the movement of the propeller.

Since 2006

Years Industry Experience

Workers

Customer Service

Get Started

Stop worrying about backdriving – our self-locking screw gears have got you covered

Contact Us

Mail:[email protected]